The Power of Connection

- Designed and engineered to perform thousands of cycles without failure

- Ergonomic designs

- Handcrafted in house machined components and contacts

- Male and Female contacts

- Manual air ejected and dual action designs

- Consistent Connection creates Reliable Test Verification

- Able to mate with product causing no wear or damage

- Connects without impacting the products integrity

- Connectors and harnesses with quick connect Amphenol

- Handmade harnesses with long lasting strain relief

- Produced to meet the demands of the harsh manufacturing environment

- Operates on our Solid State I/O Board

- Utilizes PC and PLC interface for full network reporting

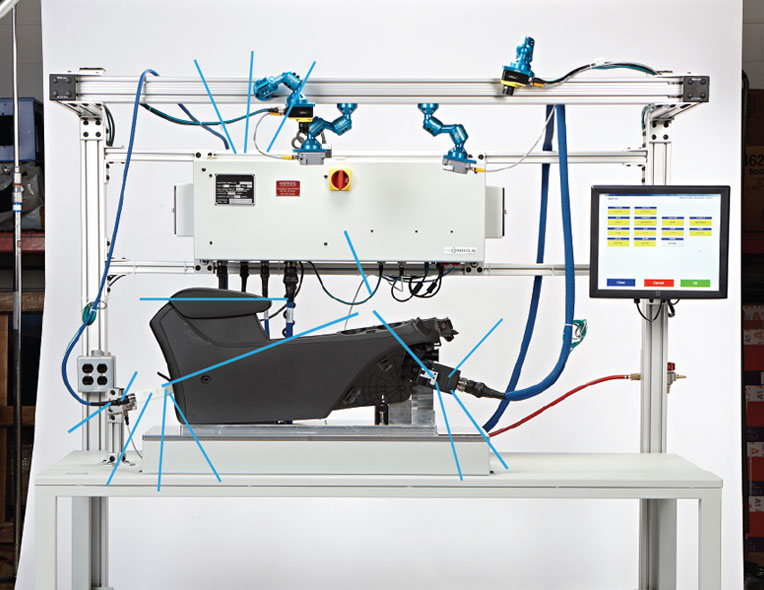

Occupant Sensor Certification Case Study

Test Products Inc. (TPI) was contracted to develop an electrical testing system for occupant sensor calibration and certification. This is important because this sensor is integral to the passenger supplement restraint system, particularly the airbag. Depending on the weight of the passenger, the intensity of the airbag deployment is compensated. In order for this system to work properly, the occupant sensor must be accurately calibrated. A key part of this system is to collect test data and provide individual traceability to certify safety. The TPI team designed and built an innovative system to provide accurate inputs to the system while communicating using a sophisticated protocol to accurately read the data needed for proper calibration and certification of the device. Before the TPI solution was introduced to the industry, the test, at two measurement points, took almost 50 seconds. TPI‘s system reduced the test time to 34 seconds, increasing throughput of production and resulted in significant financial savings and increased efficiency for the client without sacrificing accuracy or quality. The client stated that the TPI system was the “best and most accurate” testing equipment they have employed in decades. As a result of the successful project, TPI has been approved to produce future testing systems for the client. Contact us to reduce test time, improve quality, and increase profitability.Our Mission

To invest our time and talent to create custom electrical testing equipment and foster our treasured partnerships towards mutual success.

Our Purpose

TPI was founded over 40 years ago to provide innovative solutions to the unreliable electrical testing equipment plaguing the manufacturing sector. At TPI we believe that by taking the time and engaging our talent we can create Electrical Testing Systems that Verify and Validate like no others.

Our Process

Utilizing the Powers of Connection and Partnership, we’re able to customize testing solutions to meet the unique needs of our customers, regardless of their industry. We want to fully understand your issues in a quality control system, allowing us to ultimately provide you with the best solution.

Your Payoff

Custom electrical testing equipment you can rely on for accurate results can be the difference between making a profit or eating a loss. We utilize extensive experience to create long-lasting testing equipment built to withstand harsh conditions. This translates to increased First Time Quality and reduced rework and warranty costs.

Contact us today to learn more about how the Power of Connection can elevate your custom electrical testing capabilities.