Our Line of Electrical Test Products

In addition to the solution-focused services TPI offers a wide selection of industry-leading electrical test products. By thinking out-of-the-box, we have developed many creative electrical test equipment, such as the Zero Insertion Force Connector, which requires minimal force to connect, as well as test algorithms and automation designed to minimize cycle time. We use the highest-grade materials in our products, including nylon, Delryn, G10 aluminum, copper, stainless steel, urethane, and wire. Our precision test equipment works within tolerances of +-.001.

Test Equipment

Our test equipment is custom designed for our customer’s application. Typical TPI Tester Configurations include Stop Station Floor Mount, Stop Station Overhead, and On-Line tool rail mounted, with a variety of line tracking options. Our testers provide for the complete electrical testing of sub-assemblies, using:

- CAN / LIN communications

- Serial data

- Resistance

- Voltage / Continuity

- Current draw

We have designed a Solid State I/O Board that is the heart of our test systems. It allows signals to the device under test (DUT) to be modified under software control. Power feeds, grounds, and test signals can be modified without requiring wiring changes or mechanical relays, which are a common point of failure. This allows our equipment to adapt easily to changes, or optional content, in the product being tested. We can send the test results to a plant network, database, or PLC system for record keeping.

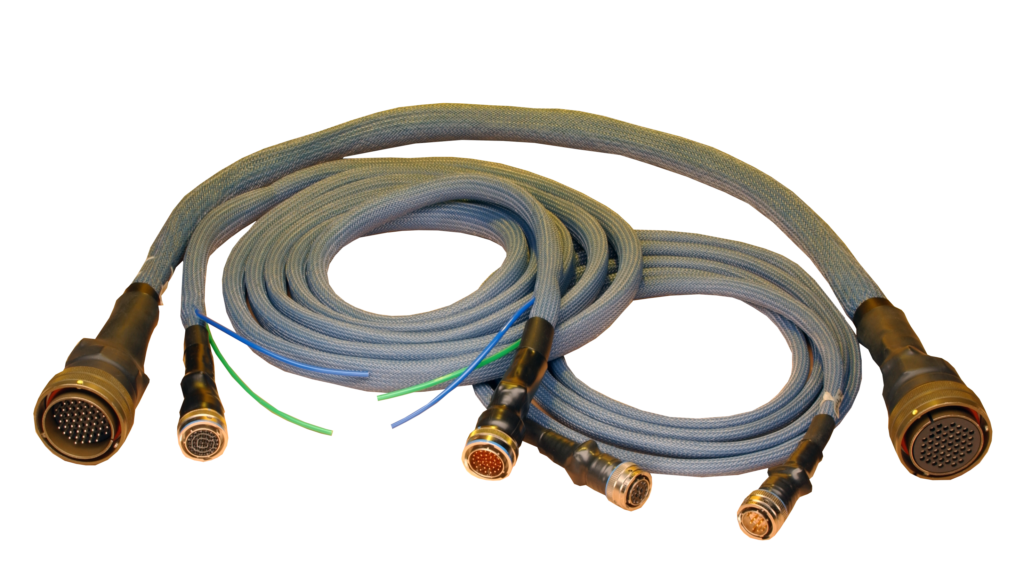

Test Connectors

TPI offers test connector solutions for your application. Our engineers, when supplied with samples of a customer’s product, will design an Interface connector to meet the customer’s requirements. Each connector is built

to handle hundreds of thousands of insertion cycles in a manufacturing plant environment, while avoiding damage to the part being tested. Typical features can include:

- Non-intrusive spring contact pins (Pogo pins)

- Custom high-current friction contacts

- Manual and pneumatic latching

- Automated disconnect

- LED indicator lights as needed

Test Fixtures

TPI has mechanical designers with years of experience designing Test and Assembly fixtures for manufacturing facilities. Our team can customize a rugged, reliable fixture to withstand the most challenging environments. One of our specialties is fixtures for programming electronic control units (ECU’s). We have designed and manufactured a variety of these fixtures, with sensors, locks, etc. as needed for the specific application.

TPI Custom Flash Fixtures

When you have modules that need to be programmed, tested, and verified for accuracy, you can rely on Test Products, Inc. We have been developing custom electrical test solutions for decades, and we design all of that experience and expertise into our flash fixtures. We have the capability to customize your testing system to use flash technology or a mechanical system for multiple modules. Contact the TPI team to discuss your flash fixture project and we’ll design a custom solution to meet your exact requirements. Download PDF.

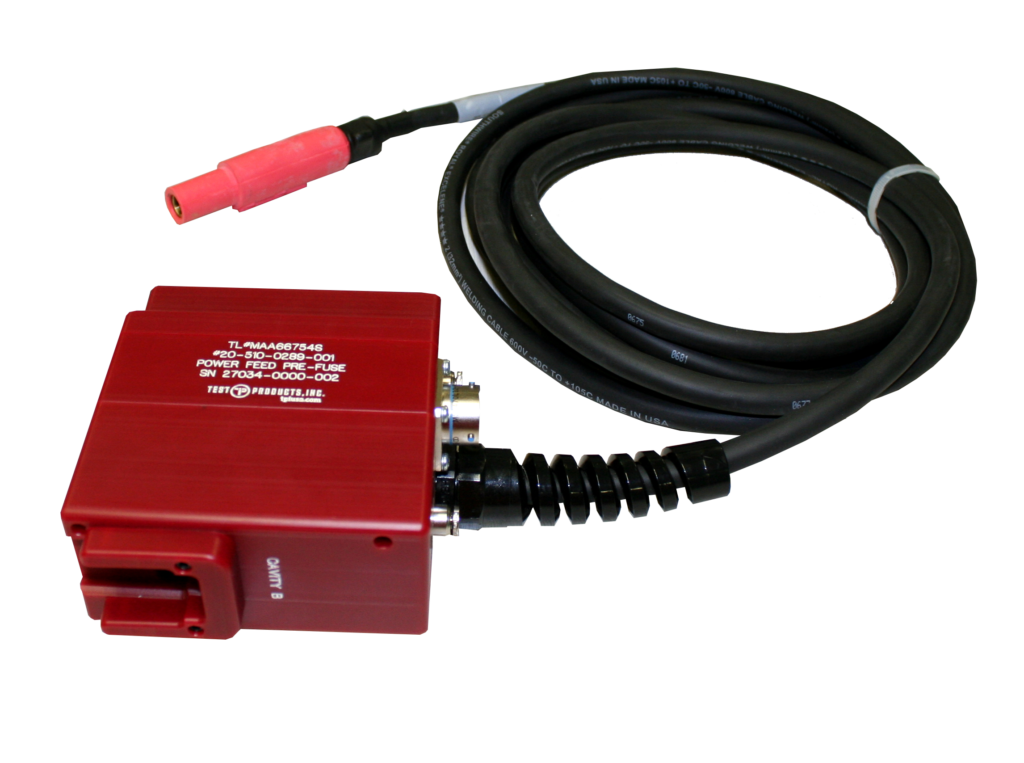

DC Power Supplies (Hot Drops)

Our power supplies provide DC power to your product during the manufacturing process. These units typically use part-in-place sensors to turn on the power after they have been connected, which eliminates any electrical transients that could cause damage. We have smart versions that can be designed to send CAN or LIN signals as needed. Voltage and current specifications can be selected to meet your needs.