Founded in 1986 • Turnkey solutions • Expertise in engineering • In house design • In house manufacturing • In house support

The Power of Test Products, Inc. (TPI) focuses on the Power of Connection to provide custom-designed and manufactured electrical testing solutions. We work closely with each client to develop a complete understanding of their testing requirements and manufacturing equipment, which allows us to design the perfect system that meets their needs.

Our comprehensive manufacturing capabilities and our team of highly skilled professionals come together to create long-lasting results. As a one-source supplier, our services include:

- Engineer to Order

- Manufacturing

- Assembly

- Custom Software & Hardware Design

- Prototype Development

- Real-time Web-based Data Feedback

- Predictive Analytics Reporting

Every TPI test system provides complete scalability to quickly adapt from the simplest handheld application to the most demanding testing program. We know that the success of our electrical testing systems, and ultimately your product’s success, relies on the Power of Connection in four critical areas.

The Power of Partnering

As a partner supplier, our commitment to customers goes beyond our electrical testing solutions. Our proactive collaborative approach allows us to tailor each system to meet the unique needs of OEMs across all manufacturing disciplines. We bring our extensive experience and expertise to every project with the goal of improving performance, productivity, and profitability through our custom testing systems.

The Power of Solutions

We work with each customer to truly understand the scope of the testing program to ensure accurate, consistent, and reliable high-end testing systems. This in-depth analysis lets us tailor a testing solution to meet your exact requirements and provide proven results while adding long-term value to your process.

The Power of Reliability

Reliable testing is critical to the quality of your product, and you need to trust that your supplier will deliver test systems that are consistent, reliable, and durable. We continually enhance and improve our technology and equipment, allowing us to build dependable electrical testing equipment that maintains tolerances of +-.001. Each unit is constructed with the highest-grade materials to ensure dependable, consistent accuracy in even the harshest manufacturing environments.

The Power of Support

True long-term electrical testing success doesn’t rest just on the initial system; it also depends on the supplier’s support. Our service team is available 24/7 for remote technical support to help when you need it. TPI proactively informs you when our system requires maintenance and maintains an inventory of replacement parts to avoid unplanned shutdowns.

Our Mission

To invest our time and talent to create custom electrical testing equipment and foster our treasured partnerships towards mutual success.

Our Purpose

TPI was founded over 40 years ago to provide innovative solutions to the unreliable electrical testing equipment plaguing the manufacturing sector. At TPI we believe that by taking the time and engaging our talent we can create Electrical Testing Systems that Verify and Validate like no others.

Our Process

Utilizing the Powers of Connection and Partnership, we’re able to customize testing solutions to meet the unique needs of our customers, regardless of their industry. We want to fully understand your issues in a quality control system, allowing us to ultimately provide you with the best solution.

Your Payoff

Custom electrical testing equipment you can rely on for accurate results can be the difference between making a profit or eating a loss. We utilize extensive experience to create long-lasting testing equipment built to withstand harsh conditions. This translates to increased First Time Quality and reduced rework and warranty costs.

Core Values

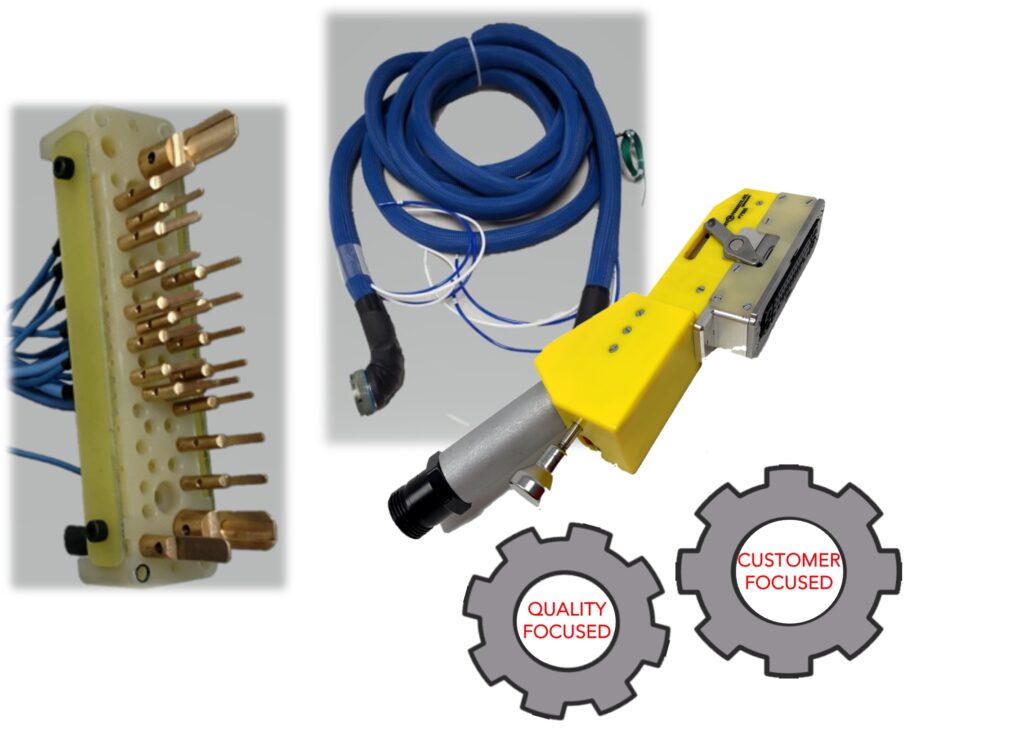

We believe in designing and building electrical test systems with these core values:

- Customer Focused

- Quality Focused

- Smart – Reliable – Devoted

- Work Ethic

The Power of Connection

Providing OEMs and Tier 1 suppliers in the transportation industry electrical verification through The Power of Connection

- Designing solutions that connect with our customers goals

- Always engineered with the connection in mind

- Ensuring that the connection to your product causes no damage or bent pins

- Power is supplied consistently every test

The Power of Connection means:

- Machined and Molded with time tested and proven methods

- Always assembled by hand like a fine time piece

- Using industrial parts and components to meet production environment

- Producing results for thousands of cycles, reporting all data to plant networks

- All products Made in our Sterling Heights Facility

- Proud to say Made in USA

The Power of Connection means:

Industrial Designed for Manufacturing

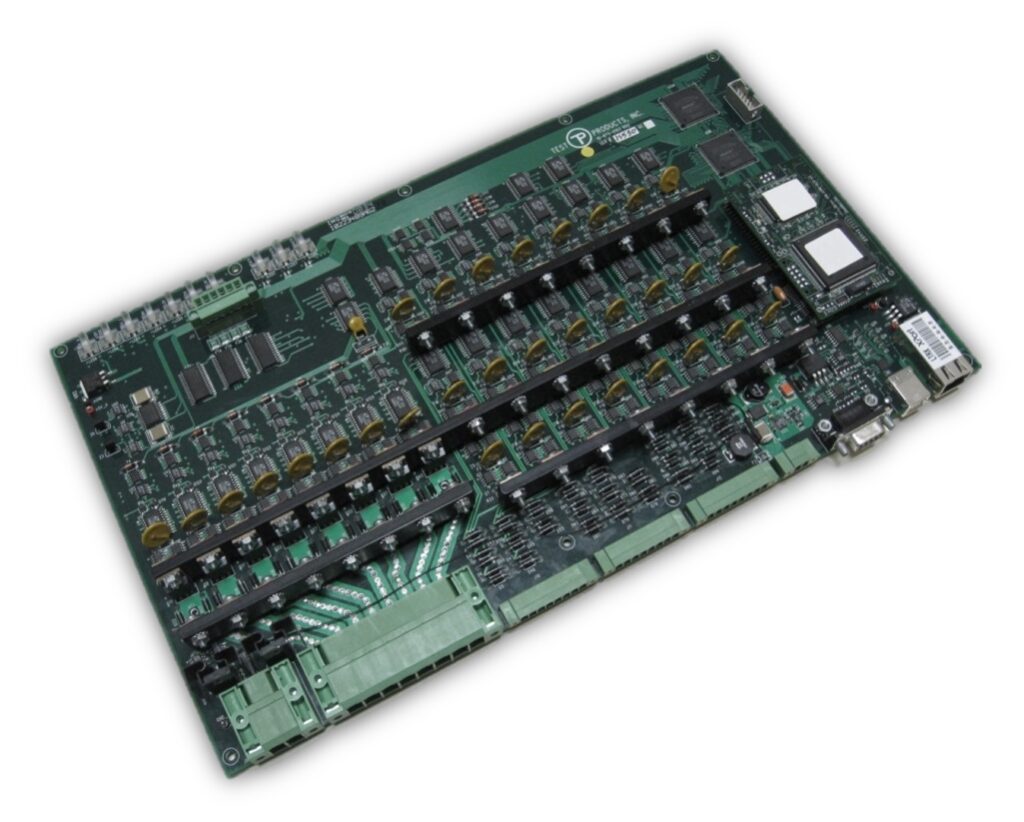

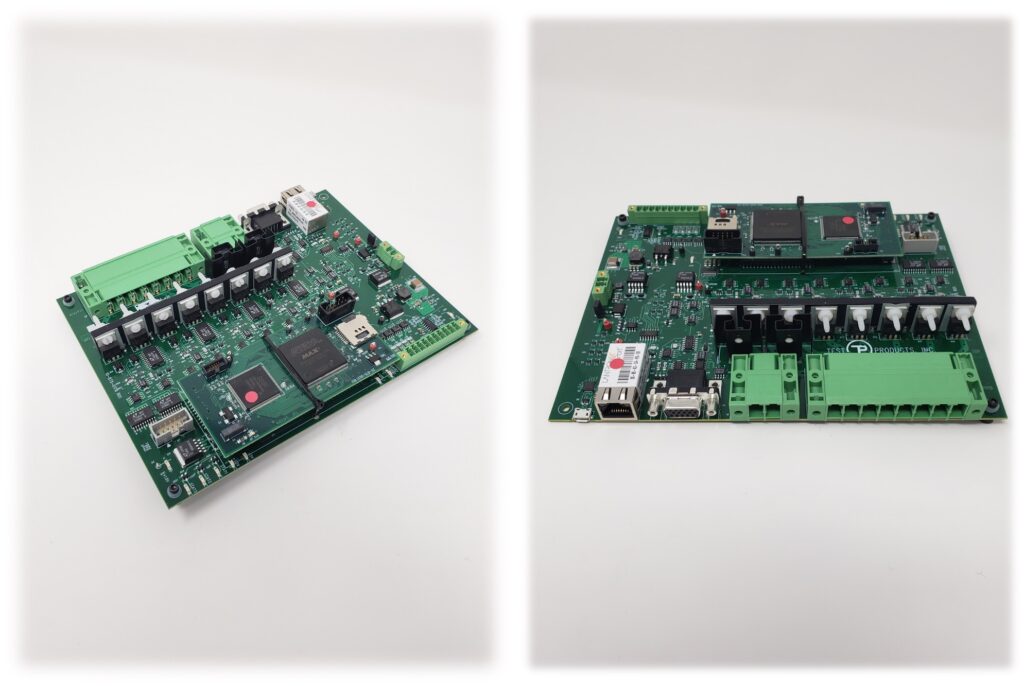

SOLID STATE I/O BOARD

- Solid state I/O board for high reliability – nothing to wear out

- 2 Board styles 8 or 32 channels of discrete I/O

- Supports CAN and CAN FD communications

- Can measure and test voltage on each channel

- Channels software configurable for feeds, grounds, and continuity

- No relays or PLCs needed

- No dedicated feeds and grounds – each pin can be reconfigured for a product change through software

- Capable of high current, 25 amps, to drive window motors, blowers, etc.

- Can measure and test current draw

- Ethernet communications to test PC

- Hundreds of boards in service

- Over 12 years of field use

- Greater than 98% reliability

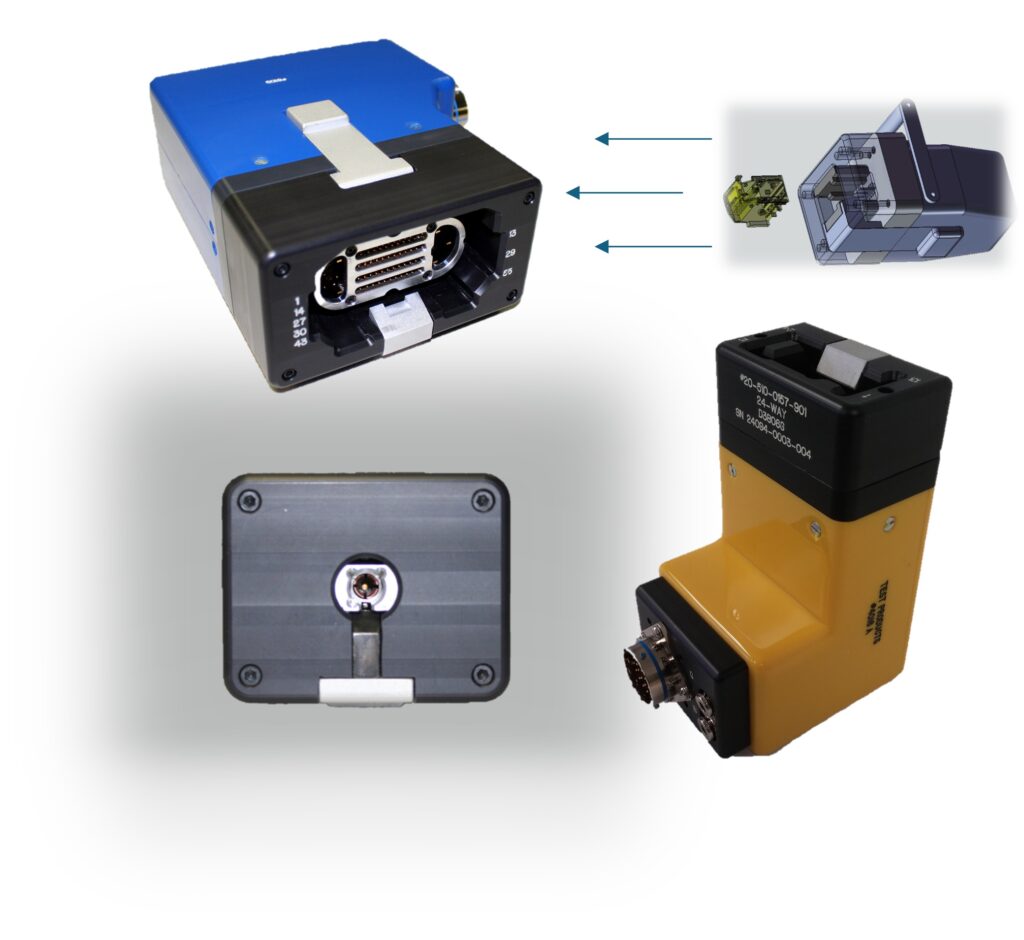

High End, Ergonomic, Reliable, Durable Test Connectors

Manual Connector

- Designed to last thousands of cycles

- Single, Dual and Fork Latches

- Multiple cavity designs

- Colorized handles to aid in connection

- Rely on the operator to mate and disconnect the product to the test connector

High End, Ergonomic, Reliable, Durable Test Connectors

Air Eject Connector

- Operator engages product to secure latches

- Connector recognizes product is seated

- Can add LED lights for operator feedback

- Switches available for operator input

- Test runs holding the part until complete

- Product is automatically ejected at the end of the test cycle

High End, Ergonomic, Reliable, Durable Test Connectors

Dual Action Connector

- Designed for High Density Product connectors

- Draws the product down into final position

- Holds product in place during test

- Ejects the product connector at the end of the test cycle

- Eliminates the possibility of damaging product contacts and pins

Dual Action Test Connectors in Motion

The Advantage of Dual Action Connector

- Designed for High Density Product connectors

- Draws the product down into final position

- Holds product in place during test

- Ejects the product connector at the end of the test cycle

- Eliminates the possibility of damaging product contacts and pins

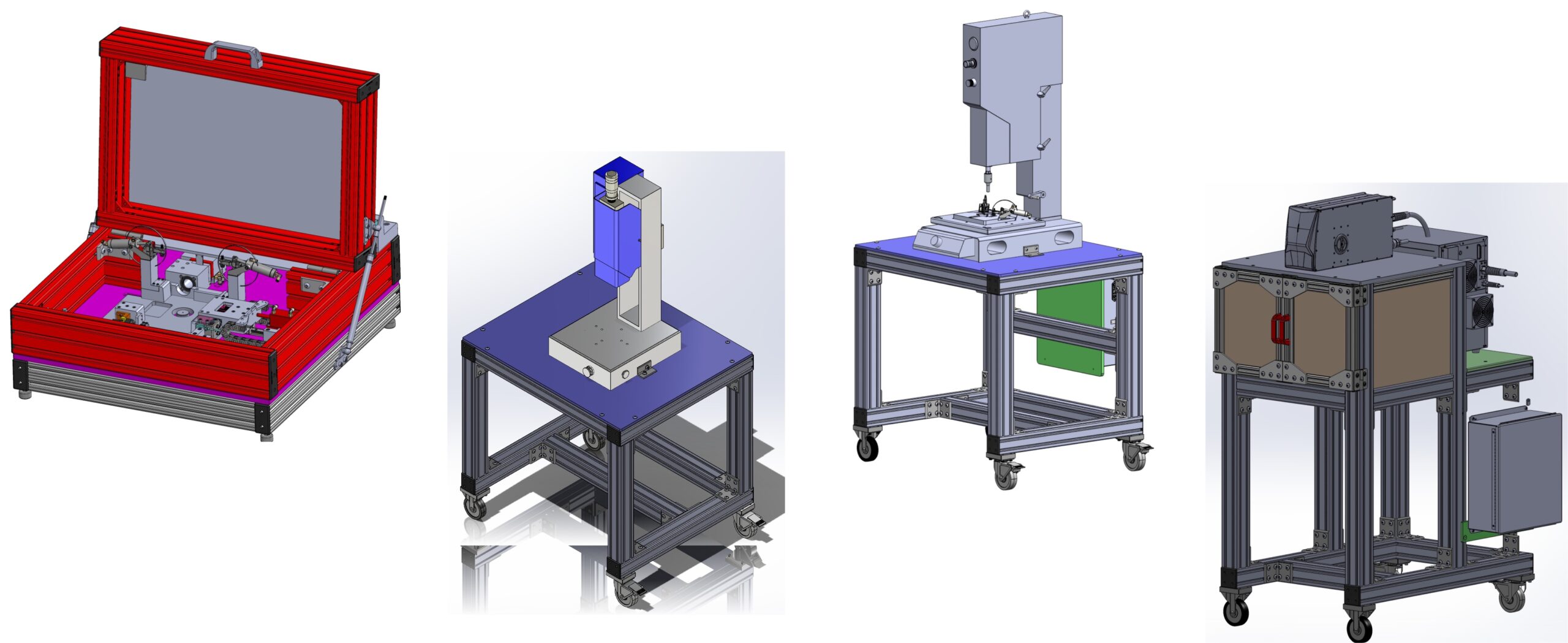

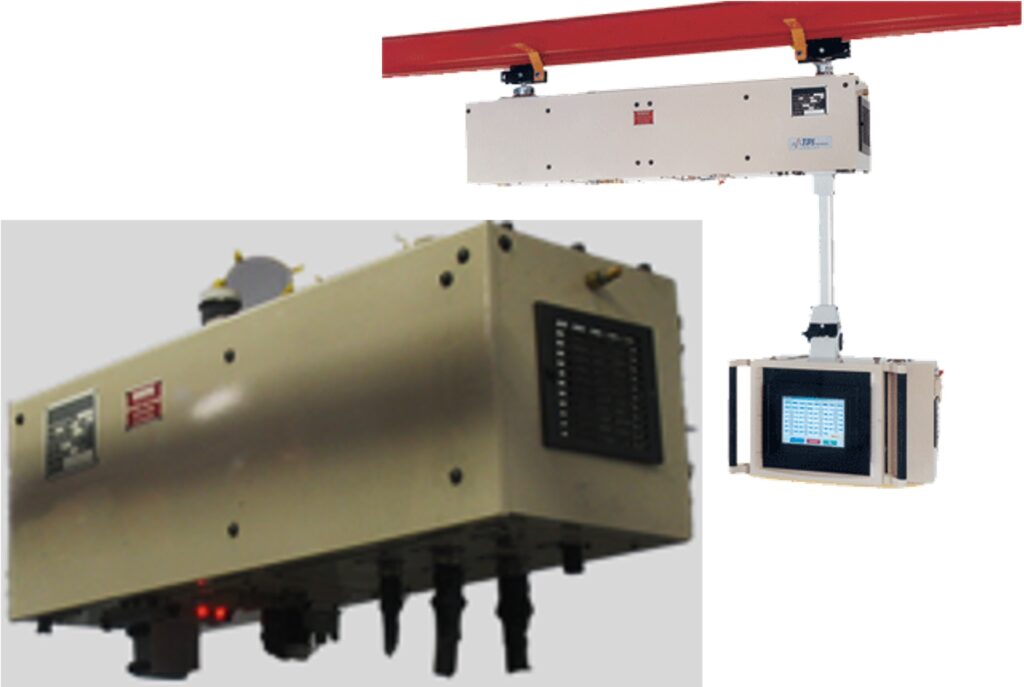

Test Systems that are Repairable, Reconfigurable, Reusable

Our Expertise

- Designed to be Durable and Reliable

- Battery Powered portable testers

Future Capacity

- Designed for flexibility

- Ability to test multiple models

- Several configurations

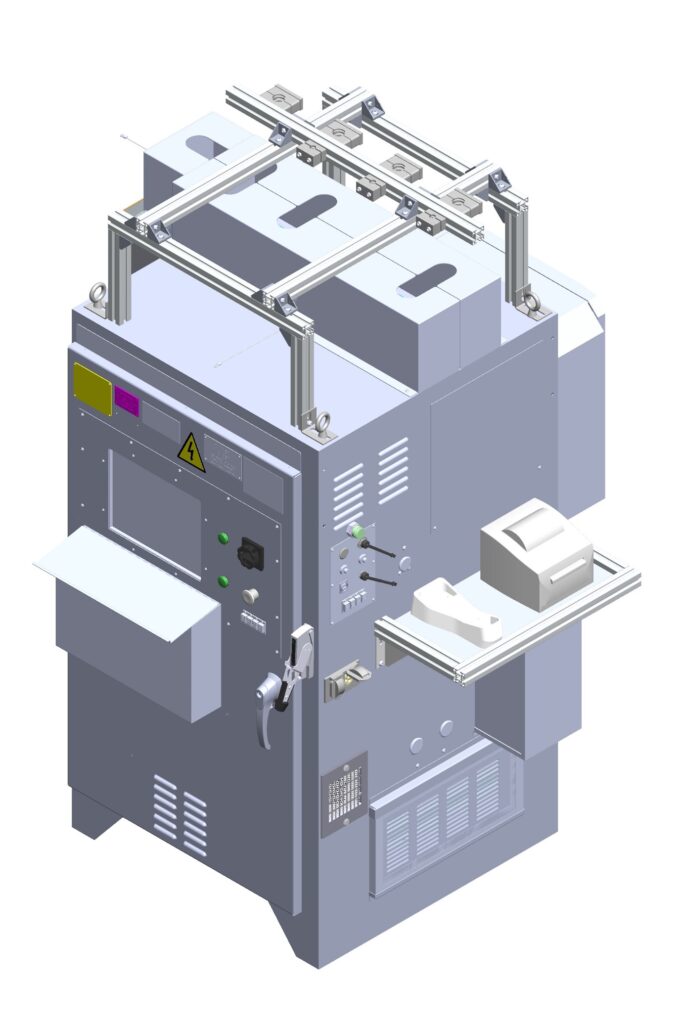

Styles of Systems

- Rail Mounted

- Table Top

- Floor Standing

- Custom Stands

Harness Management

- Manual and Pneumatic Tracking

- Reduces connector and harness wear

- Clean and easy use for operator

- Improves cycle times

Long-term Service

- Capacity to expand

- Model year updates

- Manufacturing Change Notices

Testing The Limits

- Full Assembly and Sub-Assembly

- Instrument Panel

- Counsel and Headliner

- Facia, Camera and Sensors

- Micro Cockpit

- HVAC

- EVAC and Fill Tools

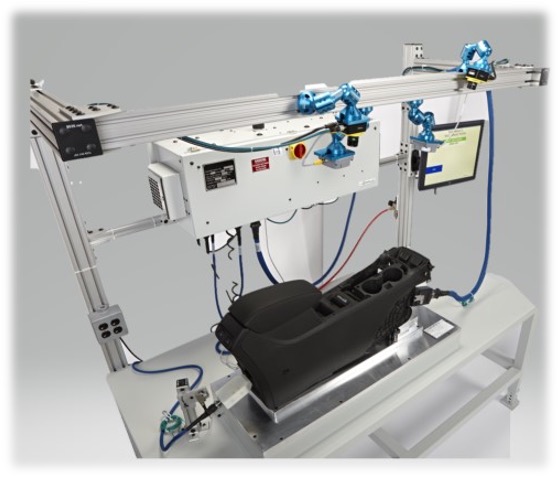

Door Test System in Action

Turn Key Solution

- Overhead Rail Mounted Tester

- Line Tracking System

- Touch Screen Display

- Air Eject Connectors

- Option/Functional Test

- Scan Build Data

- Networked Results sent to WCC or PFCS

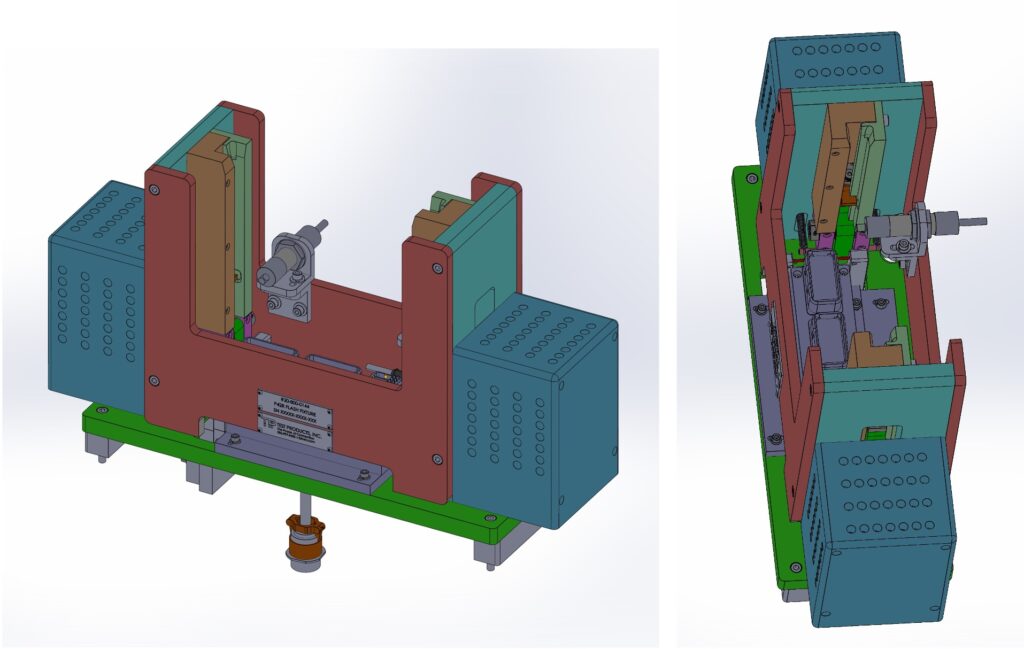

Flash Fixtures

Test Products manufacturer’s Flash Fixtures In-House.

We provide a solution to customers that delivers the software flashing operation system.

EV Charge Station

AC/DC EV Charge Stations

- All in One System

- North America, Europe, Japan(CHAdeMO), and China(GB/T)

- Charge/Discharge Test

- Simulation of Charging Stations

- Temperature Sensor Verification

- Simulation of Fault Codes

Other Testing Options