The Role of Automated Test Equipment in Modern Manufacturing

Advanced technology is rapidly revolutionizing the way we interact with our world, creating a growing demand for more cutting-edge products that utilize these innovative technologies. In order to meet the exponential growth of demand, modern manufacturing must keep pace and produce greater numbers of complex high-tech gadgets. This poses unique challenges for manufacturers across the globe. However, the solution is simple: automated test equipment.

The Power of Connection with Automated Test Equipment

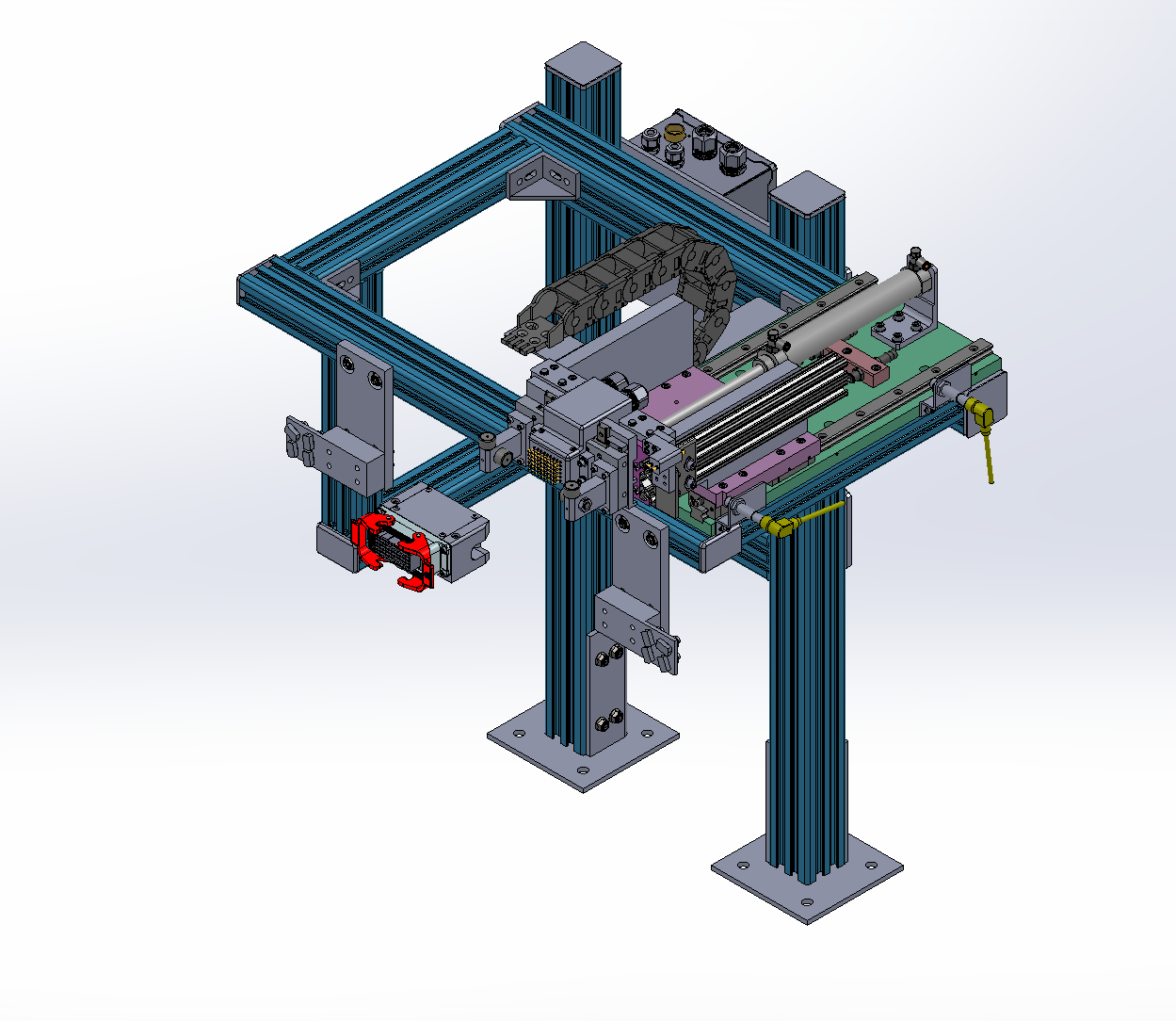

The key to meeting the growing demand for complex products is for manufacturers to embrace these technologies themselves, allowing them to produce more, quicker, and of better quality. The biggest obstacle, however, is ensuring that these complex, highly advanced technologies will function exactly as intended after manufacturing. With the prevalence of extremely sensitive electronics, ensuring functionality and reliability is vital to prevent expensive recalls and rework. Custom automated test equipment, either integrated into production lines or as part of a quality control facility, is the only way to ensure complete functionality without extremely high labor costs.

Improve FTQs

Automated test equipment is one of the first lines of defense against quality escapes, instantly alerting manufacturers of any defects at the earliest possible moment. This allows them to halt production and address the issue before it results in expensive out-of-box failures. With real-time data tracking capabilities, automated testing equipment can also help identify patterns, providing valuable manufacturing insights for overall improvement opportunities.

Streamline Production

The versatility of automated test equipment allows manufacturers to integrate advanced quality control measures into their production lines, reducing transfer requirements and cycle times. Complex electrical devices can be validated in-process, every step of the way, drastically reducing labor requirements and increasing production speeds. By streamlining the production process with automated test equipment, manufacturers will enjoy long-term cost savings.

Enhance Overall Productivity

With the tedious and highly sensitive testing controlled by sophisticated technologies, skilled labor can be better utilized for tasks that require the human touch. This will effectively help boost productivity, as employees are happier when truly engaged with their work. Between the faster cycle times, greater volume capacity, improved FTQs, and better-allotted resources, overall productivity–and profitability–is greatly enhanced.

Through the Power of Connection, Anything is Possible

Custom automated test equipment is the key to modern manufacturing, and at TPI we embrace the Power of Connection to develop the best solution for your product testing requirements. Contact us today to learn more or request your quote and experience the Power of Connection for yourself.